Overview

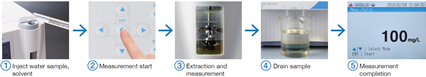

The OCMA-500 Oil Content Monitor has been redesigned for even better operability, maintaining its user-friendly features. After injecting the sample, all you have to do is press a button to get the monitoring operation done quickly, from oil extraction to sample measurement and draining. This machine is easy for anyone to use.The OCMA-500 cuts solvent consumption by 20% compared with our previous products, reducing environmental impact. It also reduces the running costs.

Features

-

Fully automated one-touch operation, from oil extraction to sample measurement and draining

-

Reduced environmental impact and running costs

(20% cut in solvent consumption) -

With no need for a solvent evaporation process, the OCMA-500 offers easy operation, and can detect even oils with low boiling points.

Improvement of operability

-

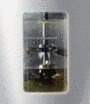

Backlit extraction tank (patent applied for)

The extraction tank is equipped with LEDs. Illuminating the tank makes it easy to check the phase separation between sample and solvent.

→

→

Before extraction After extraction

*The color depends on the sample. -

Color graphic LCD

The OCMA-500 comes equipped with a 3.5-in color graphic LCD. Menus and measurement data can be clearly seen -

USB flash memory drive port

Storing data on USB flash memories enables easy data management on PCs. -

Unit conversion

Inputting measurement conditions can change the units displayed (mg/L, mg/kg, mg/g, and mg/PC) as the user needs.

Various Application

-

Factory dranage

For monitoring final discharge water

-

Ballast water, Bilge

For monitorng discharge from ships

-

Vehicle mentenance site and gas station

For monitoring water quality in sorrounding areas

-

Others

Water quality survay based on environmental standard.

For monitoring final discharge from petroleum refinery plant.

For oil dispersion reserch at time of an accident.

Datasheet